The Spot test

One of the most important tests to check the bitumen quality is the spot test. It can show us whether the bitumen is damaged during overheating or not. Sometimes it can help to find out if the bitumen is pure or not.

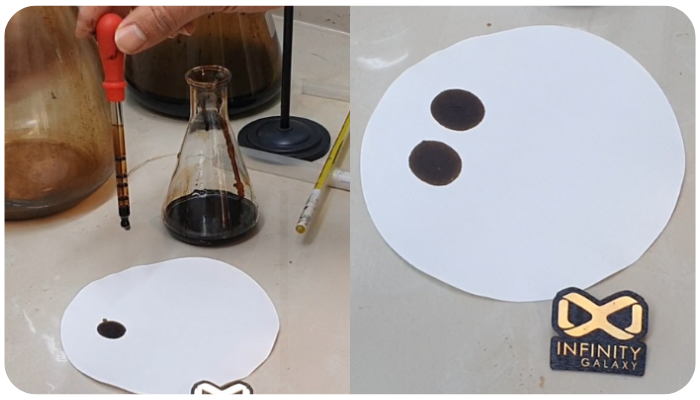

In short, you should dissolve 2 grams of bitumen sample in 10ml of solvent in a flask. Then place a drop of solution on the filter paper. The trace that appears on the filter paper is the result of the test.

The Field test of bitumen results is reported as positive or negative. The positive result confirmed the damage and the negative result shows the desired quality of bitumen.

Now let’s answer why the spot test of bitumen is important.

For a road construction project, it is important to use high-quality pure bitumen to have a safe pavement. We can thus have asphalt with a longer lifespan and less damage.

So here the importance of this test becomes obvious because overheating causes cracking. Cracking breaks the long-chain molecules, which is one of the factors that make bitumen sticky. Cracked bitumen is not a good binder because it is not ductile enough.

Also, Cracked bitumen is sensitive to the aging process. This means that during the time because of the hot temperature and loading it can crack easily. As a result, bitumen with a positive spot test is not an economical choice for pavement because it has a lower life span.

Also read: Top 10 require Bitumen Lab Tests for Pavement Construction

In the following video, you can see the steps of the spot test of bitumen based on the AASHTO T 102 standard.

The procedure

- To perform the test first, you should weigh 2 grams of bitumen sample in the flask.

- Then solvents must be added to the bitumen sample so pour 5 ml of xylene and 5 ml of normal heptane into the flask as solvents.

- Rotate the flask for 5 seconds and then place it in the boiling water bath for 55 seconds.

- This process should be repeated 7 times or more until the sample is completely dissolved in the solvent.

- After that, you should place the flask in the water bath at 32 degrees Celsius. For reaching the sample to maintain temperature, 15 minutes is suitable.

Finally, place a drop of solution on the filter paper.

If you see the drop trace is brown with a black center, then report the test positive.

But If the trace of the drop is completely brown, or yellowish-brown you should repeat the Field test of bitumen to make sure this is a definite result. Because insoluble material can appear during this time.

So place the stopper on the flask to prevent solvent evaporation.

After 24 hours, to reach the desired test temperature, you should place the flask in the water bath at 32 degrees Celsius for 15 minutes.

Again place a drop of solution on the filter paper.

- If the trace of the drop is brown with a black center, report the test positive.

- If the trace of the drop is completely brown, or yellowish-brown, report the test negative.

Bitumen is used in the road building, waterproofing, and soundproofing industries, as well as paint production.

By-products of crude oil refinement include bitumen. Globally, over 100 tons of bitumen are consumed each year for road construction.

Source: Infinity Galaxy

PIGSO Learning is a leading ed-tech company in the higher education segment. Focus on research, learning, and practical education.