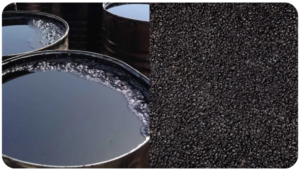

Bitumen? How Is It Produced?

Bitumen is used in the road building, waterproofing, and soundproofing industries, as well as paint production.

By-products of crude oil refinement include bitumen. Globally, over 100 tons of bitumen are consumed each year for road construction.

Bitumen test: Why is it important?

The desired properties of bitumen depend on the mix type and construction. Bitumen should have the following characteristics in general.

- Bitumen should not be sensitive to temperature; it shouldn’t become too soft or unstable in hot weather, and it shouldn’t become too rigid in cold weather.

- At the time of mixing and compacting, the bitumen should have an appropriate viscosity. Suitable grades of cutbacks or emulsions can be used or the bitumen and aggregates can be heated prior to mixing to achieve this.

- In the mix, there should be adequate affinity and adhesion between the bitumen and aggregate.

The behavior of bitumen under stress is complex. Almost all bitumens exhibit viscoelastic behavior. Temperature and time affect their resistance to deformation.

The quality and different properties of bitumen for pavement construction are tested in laboratories. Bitumen is a black or brown mixture of hydrocarbons obtained from partial distillation of crude oil.

10 Major Bitumen Tests:

There are a number of tests to assess the properties of bituminous materials. The following tests are usually conducted to evaluate the different properties of bituminous materials.

- Penetration test

- Softening point test

- Ductility test

- Viscosity test

- Specific gravity test

- Solubility test

- Flash and Fire point test

- Loss on heating test

- Spot test

- Float test

The infographic below by Infinity Galaxy shows the 10 most practical tests of bitumen, there

aims, and their procedures.

PIGSO Learning is a leading ed-tech company in the higher education segment. Focus on research, learning, and practical education.