The recent collapse of a section of National Highway 66 at Kooriyad, Malappuram, is a geotechnical failure where the foundation soil could not support the imposed loads of the bridge approach and retaining structures. According to the initial investigation by the National Highways Authority of India (NHAI) and expert panels, the primary causes were:

Technical Aspects Behind the NH-66 Bridge Section Collapse

1. Foundation Soil Inadequacy

- Soft, Waterlogged Subsoil:

The collapsed section was built over a reclaimed paddy field, an area with soft, compressible, and water-saturated soils. Such soils have low shear strength and low bearing capacity, making them unsuitable for supporting heavy embankments without substantial ground improvement.

- Failure to Improve Soil:

The contractor did not adequately improve or reinforce the foundation soils before loading them with a high embankment and RE wall. No effective ground improvement techniques (such as stone columns, preloading, or deep soil mixing) were implemented, despite the known risks.

2. Excessive Embankment Load

- Weak Subsoil and High Embankment Loads:

The area consisted of loamy, weak subsoil, which was unable to bear the heavy loads from the high embankment and reinforced earth (RE) wall. The subsoil’s low bearing capacity was not adequately addressed during design and construction.

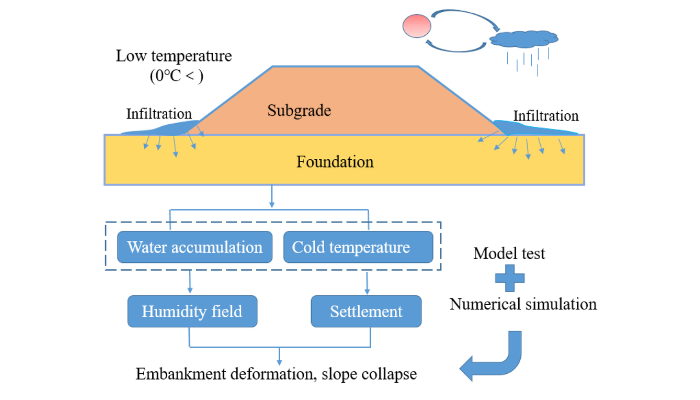

3. Inadequate Drainage and Water Management

- Obstructed Natural Water Flow:

The construction blocked natural drainage channels and watercourses in a region already prone to waterlogging. This led to increased pore water pressures and further reduction in soil strength.

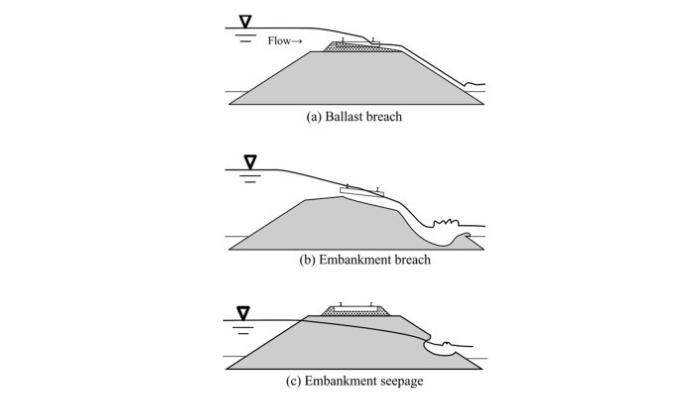

- Water Seepage and Accumulation:

Poor drainage and continuous water infiltration from adjacent fields and streams exacerbated soil saturation, triggering progressive failure beneath the embankment.

4. Design and Oversight Failures

- Negligence in Soil Testing and Design:

The concessionaire failed to conduct thorough geotechnical investigations and did not verify the soil’s bearing capacity before finalizing the design. The design did not account for the worst-case soil and hydrological conditions.

- Ignored Expert and Community Warnings:

Warnings from the Geological Survey of India and residents about the risk of collapse due to soft soils and waterlogging were not heeded. The design and construction proceeded without adapting to these site-specific challenges.

5. Progressive Failure Mechanism

- Settlement and Lateral Spreading:

As the embankment load increased, the soft foundation soil underwent excessive settlement and lateral spreading. Cracks developed in the RE wall and embankment, followed by a sudden collapse as the soil could no longer support the structure.

- Collapse Sequence:

The failure propagated rapidly, bringing down the RE wall, embankment, and service road, and causing a mound of debris in the adjacent paddy field. Vehicles were trapped, and the service road was damaged by falling concrete and soil.

Key Technical Failures

| Failure Aspect | Technical Cause |

| Foundation Soil | Soft, saturated, low-strength soil; no ground improvement |

| Embankment Design | High loads on weak soil; unscientific use of RE wall and soil fill |

| Drainage | Poor supervision, lack of quality control, and ignored warnings |

| Site Investigation | Inadequate soil testing; ignored site-specific risks |

| Construction Quality | Excessive settlement, lateral spreading, and sudden bearing failure |

| Failure Mechanism | Excessive settlement, lateral spreading, sudden bearing failure |

Key Technical Lessons for failures in NHAI :

- Thorough Geotechnical Investigation is Essential:

- Always conduct detailed site investigations (borings, soil sampling, lab tests) to determine soil properties, groundwater conditions, and variability.

- Double-check soil reports and ensure they cover seasonal changes, especially in areas prone to waterlogging or with soft soils.

- Design for the Worst-Case Scenario:

- Account for maximum anticipated loads, water table fluctuations, and potential for soil weakening over time.

- Use conservative safety factors in design, especially for critical infrastructure like bridges and highways.

- Ground Improvement and Reinforcement:

- Where weak soils are present, implement ground improvement techniques (e.g., soil replacement, stone columns, geosynthetics, deep mixing).

- Ensure reinforced earth walls and embankments have adequate foundation support.

- Drainage and Water Management:

- Design and maintain effective drainage systems to prevent water accumulation near foundations.

- Monitor for signs of water ingress or soil saturation during and after construction.

- Construction Quality and Supervision:

- Ensure strict adherence to design specifications and construction best practices.

- Employ independent quality checks and third-party supervision, especially for high-risk geotechnical works.

- Continuous Monitoring and Early Warning:

- Use instrumentation (settlement plates, piezometers, inclinometers) to monitor soil and structure behavior during and after construction.

- Respond promptly to warning signs such as cracks, settlement, or water seepage.

Double-Check List for Geotechnical Projects

| Step | What to Check/Do |

| Site Investigation | Multiple boreholes, lab tests, and a groundwater study |

| Soil Assessment | Bearing capacity, compressibility, liquefaction |

| Drainage Design | Surface & subsurface drainage, water table control |

| Ground Improvement | Settlement, cracks, water ingress, and maintenance |

| Design Review | Independent review, safety factors, scenario checks |

| Construction Monitoring | Instrumentation, quality control, supervision |

| Post-Construction | Settlement, cracks, water ingress, maintenance |

Conclusion

The NH-66 collapse is a sobering reminder that geotechnical diligence, robust design, and vigilant construction supervision are non-negotiable in civil engineering. For students and professionals, it highlights the importance of verifying every technical aspect, from soil testing to drainage and monitoring, to ensure the safety and longevity of critical infrastructure. PIGSO LEARNING tries to investigate the infrastructure projects and prepare a case study for their learners with a Civil, Geotechncial engineering background.

References and Credit go to

- https://www.newindianexpress.com/states/kerala/2025/May/30/nhai-blames-concessionaire-for-nh-66-collapse-to-issue-fresh-safety-guidelines

- https://www.onmanorama.com/news/kerala/2025/05/29/nh-66-malappuram-collapse-nhai-project.html

- https://english.mathrubhumi.com/news/kerala/nh-collapse-in-kerala-construction-company-accepts-blame-vows-to-take-corrective-action-gutjzb44

- https://timesofindia.indiatimes.com/india/heads-roll-days-after-collapse-of-re-wall-of-under-construction-nh-in-kerala/articleshow/121496911.cms

Mayank Panchal is the founder of PIGSO Learning. He has many years of experience in teaching, curriculum development, and instructional designer in civil engineering, Mathematics, and digital marketing space. His passion for conceptual and deep research-based learning helps to understand the subject in depth.