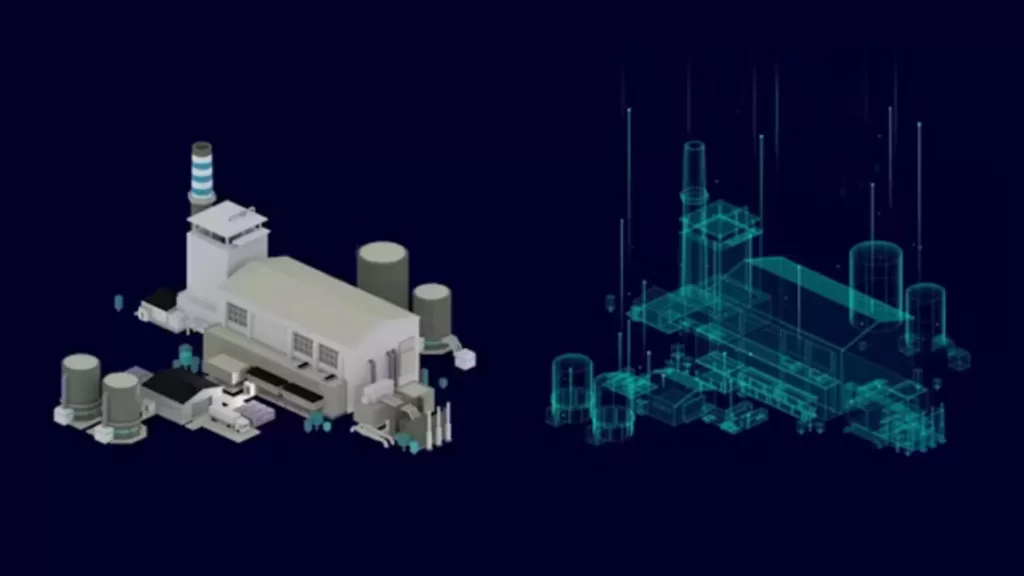

A digital twin is defined as a living, evolving virtual replica of a physical entity, which can be either an object, process, or environment that is being continuously synchronised with the real-world counterpart via real-time or near to real time data flows.

So now imagine you are constructing a site where every piece of your machinery is always on a wall, and even the structure itself is being mirrored by a digital twin which replicates real-time conditions and performance data.

This is the importance of a digital twin in construction, which is being reflected as a groundbreaking innovation that leaves a transforming impact on how projects are planned, executed, and managed.

The importance of digital twin technology in today’s construction industry lies in the ability to unify any fragmented information. Just as traditional methods focus on heavily disconnected data and manual processing, digital twin solutions are empowered to integrate insights from every stage of a project’s lifecycle, and this information can be dynamic, continuously updated, and evolving as this contemporary method improves accuracy and efficiency altogether.

What is a Digital Twin?

Digital twin, in the simplest to easiest understanding form, is a virtual representation of a real–world physical object, process, or system which uses real–time data from sensors to mirror the physical counterpart’s behaviour and performance. In construction, a digital twin means that buildings, machinery, and even site operations are replicated digitally, which enables engineers and project managers to monitor, simulate, and optimise the outcomes.

How is Digital Twin used in Smart Construction Technology?

Digital Twin is a digital copy of your real-world spaces wherein you use 3D models to interact virtually with the physical property to create more visually appealing and powerful presentations in the initial stage of planning and designing.

In smart construction, a digital twin is being used to create a dynamic virtual replicate of a physical asset, whether it’s a site, processes, or anything, by using real–time data from sensors and IoT devices.

The incorporation of a digital twin in construction is mainly carried out to represent your data, planning, and designing in a much more appealing and visually engaging manner. So by combining several types of data into a single platform where you include 3D models, sensor data, and real-time performance data, you make a way or a choice to efficiently manage your decisions and optimise your strategies.

Digital twins can also help reduce downtime and improve safety. In order to identify potential risks and take preventative measures, engineers can use a digital twin to simulate the impact of extreme weather on a building or bridge.

What is Digital Twin vs Digital Twin Technology?

A digital twin is a dynamic, virtual representation of any physical assets, system, or process, which helps to mirror the real–time state, behaviour, and performance on the other hand digital twin technology refers to a holistic ecosystem of tools, platforms and methods which makes the digital twin possible it might include data collection, integration, simulation engines and visualization system which collectively works to bring the digital twin to life.

In simple words, a digital twin is the end product, while digital technology is the framework or system that enables reaching the end product.

Digital Twin and Industry 4.0

With the rise of Industry 4.0, there has been a sudden adoption of digital twins in construction, so by leveraging cutting-edge technologies, it mainly covers,

- Sensors and IoT devices that make real–time monitoring of equipment, materials, and environmental factors possible by delivering constant data.

- Bring in the power of simulation and other modelling tools with advanced digital twin simulation that allows engineers to test out conditions like ‘what-if”, scenarios, forecast the risk, and validate their strategies before implementation.

- Also, it assists in computing massive volumes of data from construction sites, which are processed efficiently and accessible across the teams.

Additionally, there has been a rise of AI and analytics, which assist in transforming raw sensor and IoT data into more actionable insights for better and smarter decision-making.

By integrating these technologies into construction workflows, smart construction emerges as a reality where projects are more efficient, cost-effective, and resilient. In this way, digital twins serve as the bridge between traditional construction practices and the intelligent, data-driven future envisioned by Industry 4.0.

PLAXIS and Its Role in Digital Twins / Smart Construction

The concept of digital twin is central to modern technology and infrastructure development, as its core lies in virtually representing the models.

PLAXIS is a leading geotechnical simulation software that is being used widely to study and understand soil behavior, its foundation, design, and its subsurface interactions.

Under construction projects, contractors often rely on accurate predictions of how soil and rock will behave under loads, environmental conditions, and construction sequences. This is where PLAXIS becomes invaluable, providing precise, physics-based insights that support the development of reliable and intelligent digital twin applications.

By incorporating PLAXIS models into a digital twin in construction, engineers can extend the virtual model beyond surface-level structures to include the complexities of the subsurface environment. This integration enhances accuracy, ensures that ground conditions are realistically represented, and allows better-informed design and operational decisions.

Digital Twin Benefits with PLAXIS Integration

Integrating PLAXIS with a digital twin can help bring tangible results that offer smart and reliable benefits. Below are some of the benefits of integrating PLAXIS with digital twin technology

- Accuracy in geotechnical modelling: When you integrate a digital twin with PLAXIS, you experience accuracy in gathering data as complex structures appear simpler, and you understand the nonlinear behaviour of soil, and every data point appears real and accurate.

- Improved predictive capabilities: It is found that when PLAXIS and digital twin are integrated, they manage the risk and assist in foreseeing the potential challenges that may come along

- Focuses on Lifecyle: One of the key benefits of integrating PLAXIS with digital twin is its ability to maintain the lifecycle of the project, yes, from design stage through construction, operation, and many other stages in between. PLAXIS models assist in providing deep insights into soil performance and its behaviour.

- Provides safety and reliability: Safety is one of the top priorities. Integration of PLAXIS into digital twin applications ensures the provision of safety and reliability by simulating potential geotechnical challenges like ground movement, soil settlement, or slope instability. Here, engineers can anticipate and address the challenges before they face.

- Seamless integration with smart construction system: PLAXIS assists in strengthening the role of digital twin technology by integrating seamlessly with other digital platforms such as Building Information Modeling (BIM), IoT sensor networks, and advanced monitoring systems. For example, BIM provides the design geometry, IoT devices feed real-time site data, and PLAXIS supplies geotechnical simulations, all converging within the digital twin in construction. This integration creates a holistic and interconnected view of the project, enabling stakeholders to collaborate more effectively and make informed decisions faster.

Read More: PLAXIS Software: The Complete Guide for Beginners

Challenges and Considerations

As we read above, there are benefits of integrating PLAXIS with digital twin technology, but there seem to be some challenges that might be encountered, and here’s how they can be addressed for maximum effectiveness.

Data integration complexity: Managing to merge real-time sensor data with PLAXIS models can be a little troublesome, as it requires robust frameworks.

High implementation costs: When deploying a high-standard digital twin in construction (including sensors, IoT infrastructure, and other equipment and tools), it can be a little costly, especially when you are performing small projects.

Inefficiency in delivering accurate data: There can be times when it is not possible to provide accurate data, and it so happens when the soil is inherently heterogeneous, such that even advanced PLAXIS simulations need a careful calibration to ensure accuracy

Cybersecurity concerns: As smart build construction relies on connected systems, protecting sensitive design and sensor data from cyber threats becomes critical.

Skill and Knowledge Gap: Implementing and maintaining PLAXIS-driven digital twin applications requires expertise in geotechnical engineering, data science, and digital platforms skills that may not always be readily available.

To sum up, PLAXIS provides a significant value to digital twin in construction by improving accuracy, predictability, and risk management in geotechnical engineering, whereas the role of digital twin technology goes beyond the traditional modelling of providing real data in real-time or supporting smart building construction strategies it is not less to say that there are challenges but digital twin benefits offered by PLAXIS can help make construction smarter, safer and sustainable.

Step-by-step guide to integrating Digital Twins in a construction project

- Define objectives: One of the crucial steps when you decide to integrate a digital twin in your construction project is to define your project’s objective, what you wish to monitor or achieve, or optimise.

- Choose appropriate tools: When you can decide what your objective is, then you can build an approach as to which tools you will use as per the requirements of the project, such as choosing the right BIM, IoT, and AI platforms, etc.

- Create the initial model: Deploy BIM to build the foundation of your digital twin, which can be best suited for your project’s purpose.

- IoT devices: Enable sensors for real-time data collection.

- Establish data pipeline: Make sure you establish a clear pipeline with secure, real-time data flows for insights.

- Analyse and visualise: Try to use AI to derive insights and simulate scenarios.

- Iterate and update: Make it a practice to evolve the model with feedback continuously.

Conclusion

To wrap up, it is understood that digital twin is a massive innovation in the construction industry and therefore, it is practical, reliable, and accurate, as it allows for faster construction projects, while being smarter and safer. This blog even helps you to understand how integrating PLAXIS and a digital twin can be beneficial in the long run. So whether you’re managing a single job site or shaping an entire city block, having a real-time, data-driven view of your project gives you a serious edge.

Now take your career to the next level with PIGSO LEARNING expert-led PLAXIS Training Course Online. Gain hands-on experience, earn industry-recognised certifications, and unlock new opportunities in geotechnical engineering.

Enroll now and stay ahead in your professional journey. Let us help you elevate your knowledge and learning with PIGSO LEARNING..

Contact us to know more.

Mayank Panchal is the founder of PIGSO Learning. He has many years of experience in teaching, curriculum development, and instructional designer in civil engineering, Mathematics, and digital marketing space. His passion for conceptual and deep research-based learning helps to understand the subject in depth.