Modern engineering simulation and computational analysis heavily depend on software tools for designing innovations. Altair produces Hypermesh as a finite element analysis (FEA) pre-processing software, which serves as a robust tool.

Hypermesh stands out because of its ability to mesh different domains in addition to its wide industrial range. During this time, it is essential to understand both Hypermesh software uses together with its fundamental importance for engineering work across contemporary industries.

This blog explores Hypermesh Altair fundamentals while illustrating its role in designing 3D meshes alongside a review of elements and materials before describing analytical operations and their integration with Ansys and Abaqus solvers and other platforms. This discussion will explore the industrial usage of Hypermesh in aerospace, automotive, and medical engineering. Let’s begin!

What is HyperMesh?

Altair Engineering developed HyperMesh as a leading pre-processing tool for finite element analysis (FEA) meshing. Engineers use Hypermesh to transform geometric objects into meshes to analyze physical system behaviors through simulations of stress, thermal distributions, and fluid dynamics. HyperMesh achieves its meaning from its outstanding capability to process intricate and massive models.

What is Hypermesh Altair used for? Various engineering sectors utilize HyperMesh primarily to generate meshes that analysis solvers require as inputs. The tool operates with diverse solver interfaces, which allows it to serve multiple industries. HyperMesh Altair operates as an essential tool across aerospace, automotive, and medical sectors to deliver accurate simulations.

Core Features of Hypermesh

Hypermesh Altair offers a rich set of features designed to handle both simple and highly complex simulations. Some of its key capabilities include:

Meshing Tools

HyperMesh Altair gives its users access to sophisticated mesh generation tools that support the development of both structured and unstructured mesh topology. Engineers can use these tools to divide complex geometries into small elements for optimizing finite element model resolution and accuracy. Simulation accuracy depends on the meshing functions regardless of simple or complex design types.

Mesh Quality Control

The strong mesh quality control utilities stand out as a central capability within Hypermesh Altair software uses. Real-time mesh assessment capabilities in these tools help users validate element conditions for delivering optimal simulation precision. The mesh quality control tools allow engineers to inspect poor mesh qualities so they can adjust the mesh and reduce analysis errors.

Geometry Cleanup

Using Hypermesh, one can access tools meant to clean up CAD models before the meshing process begins. The cleanup tools eliminate unrequired data while optimizing difficult shapes to prevent mesh generation problems. The integrity of the model requires absolute attention in this step to ensure proper suitability for accurate analysis.

Material Property Assignment

Through HyperMesh Altair, users have the ability to set particular material characteristics to varying model elements. Users define density alongside elasticity and thermal conductivity properties to achieve real-world simulation accuracy, which yields dependable simulation results.

Solver Interface

Users gain access to hassle-free connections with multiple solver solutions, including Ansys, Abaqus, Nastran, Optistruct, and Radioss, through the capabilities of Hypermesh Altair. Engineers benefit from broad solver compatibility, which enables model export and execution across multiple platforms and simulation techniques.

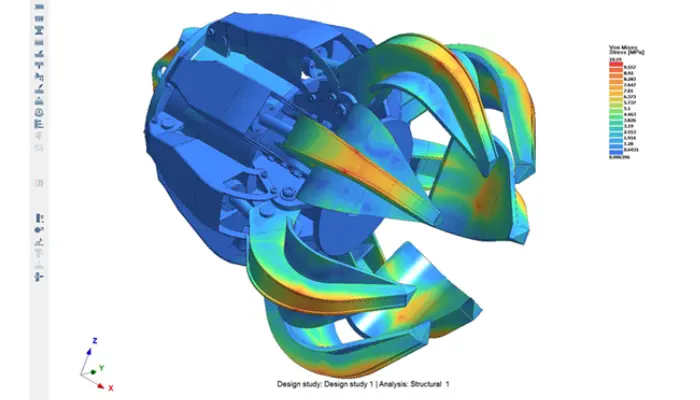

Hypermesh 3D Meshing

The primary feature of Hypermesh Altair enables the creation of 3D meshing features. The generation of 3d meshing is essential in modeling complex three-dimensional geometries, particularly for detailed structural, thermal, and fluid dynamics analyses.

The software partitions geometry into easy-to-analyse elements during Hypermesh 3D meshing operations. Realistic simulation results emerge from the software because it divides complex 3d shapes into smaller mesh parts.

Engineers select their meshing approach between the tetrahedral, hexahedral, or prism meshes based on their geometry and simulation requirements.

Read more in our blog: FEA – Finite Element Analysis – A Comprehensive Guide

Hypermesh Element Types

Simulation behavior of a structure depends fundamentally on the selected Hypermesh element types. Elements exist in different types according to geometry and analysis needs, which fall under these categories:

Shell Elements

Thin-walled structures of plates and shells require shell elements for their simulation model. Shell elements measure stress and strain alongside deformation effects in structures such as car body panels and aircraft wings.

Solid Elements

Three-dimensional solid elements represent volumetric shapes that perform essential stress, thermal, and structural analysis on components with meaningful dimensions.

Beam Elements

Structural members and frames, as well as beams, achieve maximum efficiency for axial forces along with bending moments alongside torsional loads.

Rigid Elements

The application of rigid elements happens to components that resist deformation when subjected to force. Engineers utilize rigid elements to replicate fixed elements and functional constraints and physical joints in their numerical models.

Composite Elements

These elements allow representation of materials featuring layered structures and directional strength patterns, including carbon-fiber composites. High-performance industries such as aerospace and motorsports depend heavily on composite elements.

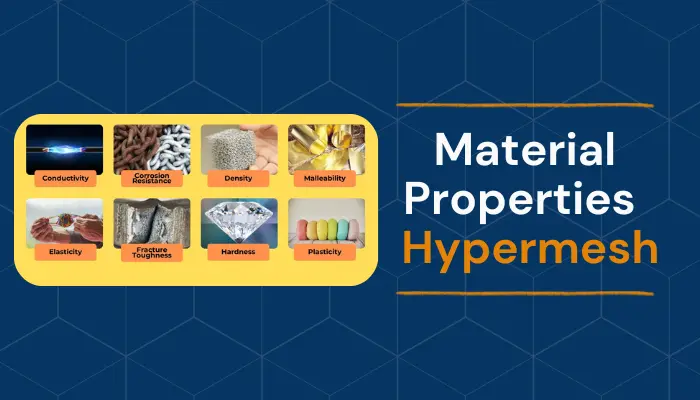

Hypermesh Material Properties

With its material property definition suite, engineers can develop precise simulations of how materials respond to different load conditions along with environmental exposure. Among the main material property types HyperMesh suite users can establish are these properties.

Elastic Properties

Young’s modulus and Poisson’s ratio, along with other elastic attributes, provide the fundamental basis for representing elastic material responses. The material stiffness and elastic shape recovery properties of a material derive from these fundamental properties. Users within the Hypermesh software platform provide these values to make calculations that predict elastic material deformation under stressing conditions.

Plasticity Properties

The essential characteristics for predicting permanent deformation in materials are plasticity properties. Through its interface, Hypermesh enables users to set yield stress and hardening behavior together with additional criteria essential for defining plastic material properties.

Modeling both primitive metals and plastics alongside other materials needing stress-based transformation requires adequate plasticity properties in the system.

Thermal Properties

The simulation of heat transfer together with thermal stress analysis in materials depends heavily on the properties that measure thermal behavior, including thermal conductivity and specific heat.

Users can utilize Hypermesh to set material properties, which makes possible simulations that simulate temperature-related behavior changes affecting material response through expansion and contraction effects.

Regional Material Assignments

Users can set material properties that automatically link to designated areas of the model through Hypermesh. Users gain precise material control over model sections because this functionality permits simulation checks regarding varying material properties throughout the whole geometry structure.

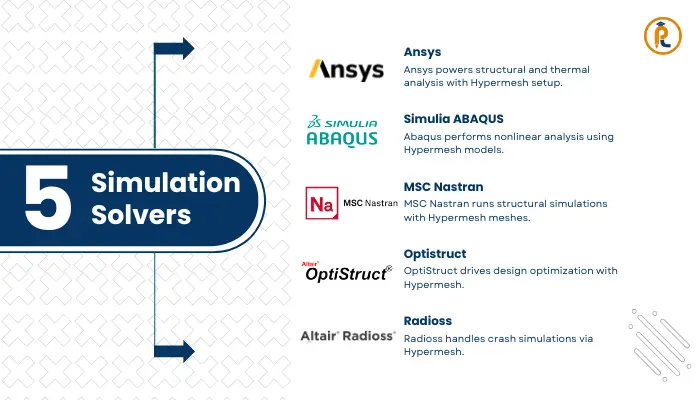

Solver Compatibility: A Core Advantage of Hypermesh

Using Hypermesh, Altair allows engineers wide compatibility with leading simulation solvers. Engineers can achieve efficiency and accuracy in their engineering workflows because this flexible platform supports model compatibility between different platforms. The most common solvers that Hypermesh interfaces with include

Ansys—For Multiphysics Simulations

The solver Ansys provides extensive power for structural, along with fluid dynamics and thermal analysis applications. The direct model export capabilities within Hypermesh for high-resolution meshes and setups create simplified workflow processes for engineers who tackle complex multiphysics problems. Check out our ANSYS Training Program designed to build practical skills step-by-step.

Abaqus—Advanced Nonlinear Analysis

The nonlinear and dynamic analysis features of Abaqus are prominent within its product range. Engineers performing plastic deformation or contact modeling or advanced material behavior simulations benefit from Hypermesh integration for setting up models prior to Abaqus analysis. Learn Abaqus Software with our Abaqus Training.

Read more in our blog: What is the best FEA Software for you: ABAQUS or ANSYS

Nastran—Widely Used in Structural Engineering

Nastran operates as the primary software choice for both aerospace and automotive companies to run linear alongside nonlinear structural simulations. Through Hypermesh, users can produce fast and accurate meshes along with data preparation solutions precisely compatible with Nastran input needs for handling large-scale simulations.

OptiStruct – Optimization and Lightweight Design

The structural optimization capability comes from OptiStruct, which operates as another solver under the Altair brand. The optimization tool offers support for topology along with size and shape adjustments. HyperMesh integrates natively with OptiStruct to accelerate lightweight design development for aerospace and automotive sectors.

Radioss—High-Speed Impact and Crash Simulation

High-speed complex results, such as crash tests, require Radioss to deliver exact performances. Engineers use Hypermesh to set exact contact specifications and mesh parameters, which Radioss can integrate to deliver dependable results in vital simulations

Applications & Industry Use Cases

HyperMesh Altair serves numerous industries because of its exceptional potential to manage intricate models as well as simulations. A brief investigation follows into the main sector applications where Hypermesh Altair software operates.

Aerospace & Automotive Industry

The accurate performance and durability, together with safety factors, of vehicles in aerospace and automotive sectors depend on precise simulation capabilities. HyperMesh delivers advanced meshing functionality. It lets engineers model intricate geometries and assess material behaviors under multiple testing scenarios.

The crash simulation, together with aerodynamic assessments that run through the Hypermesh system, plays an essential role in evaluating the safety and operational quality of aerospace and automotive products.

Aerospace & Structural Analysis

The safety of aircraft and spacecraft components, along with their supporting structures, requires aerospace & structural analysis for compliance with absolute standards. Through HyperMesh, analysts can perform detailed structural simulations that validate design compliance with regulations while achieving optimum weight efficiency.

Medical & Industrial Applications

Medical device manufacturers make use of Hypermesh to predict how their equipment will react when subjected to different operating conditions. Engineers develop optimized prosthetic designs through stress simulations followed by the selection of optimal materials and structural designs.

Within industrial sectors, Hypermesh serves to enhance production machinery performance alongside protecting manufacturing processes and achieving component durability.

Hypermesh Modal Analysis

Engineers perform hypermesh modal analysis as one of their essential analysis processes in engineering simulations. The analysis identifies both fundamental frequencies and structural shapes naturally occurring in the structure.

Users perform Hypermesh analysis to judge if their structure shows receptivity to resonance frequencies that threaten failure or degrade system performance.

Through modal analysis within Hypermesh, engineers identify and eliminate resonance frequencies ensuring their designs achieve stability and reliability.

Advantages of Hypermesh

Engineers across multiple industries choose HyperMesh because of its powerful capabilities, extensive solver compatibility, and customizable features. The primary benefits of the Hypermesh operating system include the following key features noted below.

1. High-Quality Meshing Capabilities

A primary benefit of Hypermesh lies in its efficient development of top-notch, precise meshes for complex geometric models. The advanced Hypermesh 3D meshing algorithms allow users to create structured and unstructured meshes and refine element quality and optimize mesh density to achieve better simulation results. The software offers real-time mesh quality feedback about aspect ratio alongside skewness and warpage, which helps engineers confirm simulation-ready mesh integrity.

2. Broad Support for Element Types

The simulation flexibility of Hypermesh arises from its solid element type alongside shell elements and beam elements and 1D, 2D, and 3D elements. The model design requires either thin-shell representation or detailed volumetric meshing.

HyperMesh delivers complete support for such requirements. Through its built-in tools, users can fix skew issues in Hypermesh while improving both solver accuracy and performance.

3. Extensive Solver Compatibility

HyperMesh connects to various leading solvers through complete integration with Ansys and Abaqus as well as Nastran and OptiStruct and Radioss solutions. Engineers have complete flexibility because they can reuse the same preprocessed model across multiple simulation situations.

The software saves time by automating deck export for specific solvers and simultaneously lowers the possibility of deployment mistakes.

4. Customization and Automation

Through its scripting feature and macro-development capabilities, Hypermesh allows users to execute repeated procedures and control their operational pipelines. The system generates increased productivity, particularly for large-scale projects, along with batch processing of models.

5. Performance & Computational Efficiency

The platform delivers optimal speed performance while working with extensive and complicated model structures. The tool cuts down computing time but preserves mesh consistency to serve industries with intensive simulation requirements.

HyperMesh Training

The goal of HyperMesh training lies in providing candidates with essential competencies that allow them to master Altair HyperMesh for improved simulation and design optimization. Students acquire three essential competencies through our detailed training program for efficiently building quality meshes while geometry correction and design optimization across the automotive, aerospace, and industrial design sectors.

Users learn complex meshing techniques and model assembly and simulation optimization through the training to solve different real-life engineering challenges. This training provides expert instruction and practical exercises to boost your design analysis productivity while improving accuracy levels.

The HyperMesh Training from Pigso Learning provides students at all experience levels the ideal pathway to build their competencies while maintaining leadership in the simulation market competition. For more information or inquiries, feel free to contact us.

Conclusion

HyperMesh Altair functions as industrial-grade engineering software that delivers robust mesh generation capabilities alongside professional-level analysis functions and multisolver connectivity for multiple domains. Engineering professionals in aerospace, automotive, and medical areas can enhance their simulation processes with effective HyperMesh understanding.

Engineers who master Hypermesh 3D meshing and element types and material properties, and analysis capabilities achieve better accuracy and efficiency when designing products.

So, what is Altair HyperMesh? As an essential workflow component, Hypermesh surpasses basic meshing functionalities by providing tools to simulate, analyze, and optimize designs across multiple applications. Enhance your skills with Pigso Learning’s HyperMesh Training and master this essential software. Start learning today!

FAQs

Q1. Which industries use HyperMesh?

The engineering software HyperMesh serves these industries: aerospace, automotive, and medical and industrial sectors to perform design optimization and structural analysis and performance simulations.

Q2. What is HyperMesh 3D meshing?

Through 3D meshing in HyperMesh, engineers can divide complex three-dimensional objects into fine elements, which results in improved accuracy throughout structural, thermal, and fluid dynamics analyses.

Q3. How does HyperMesh connect with different solvers?

Engineers benefit from simulator flexibility through HyperMesh, which allows them to utilize Ansys Abaqus and OptiStruct for running complex simulations on multiple platforms.

Q4. What is skew in HyperMesh?

When using HyperMesh, the program measures element distortion as skew because it requires accurate simulations. The proper mesh quality leads to maximum simulation outcomes.

Q5. What reasons do I have to begin HyperMesh training?

Learning HyperMesh through Pigso Learning’s training program teaches the necessary skills to generate meshes and make design optimizations using this software effectively. Learning now will enable you to excel at simulation and design.

I’m a passionate content writer who crafts compelling, audience-focused content. I specialize in turning ideas into engaging words, ensuring every piece delivers value, connects, and drives results.