- What is Finite Element Analysis?

- How does FEA work in structural and mechanical analysis?

- Steps involved in performing Finite Element Analysis:

- Importance of accuracy in Finite Element Analysis simulations

- Role of FEA in product design and development

- Advantages of using FEA for optimizing designs before manufacturing

- Finite Element Analysis Model

- FAQs

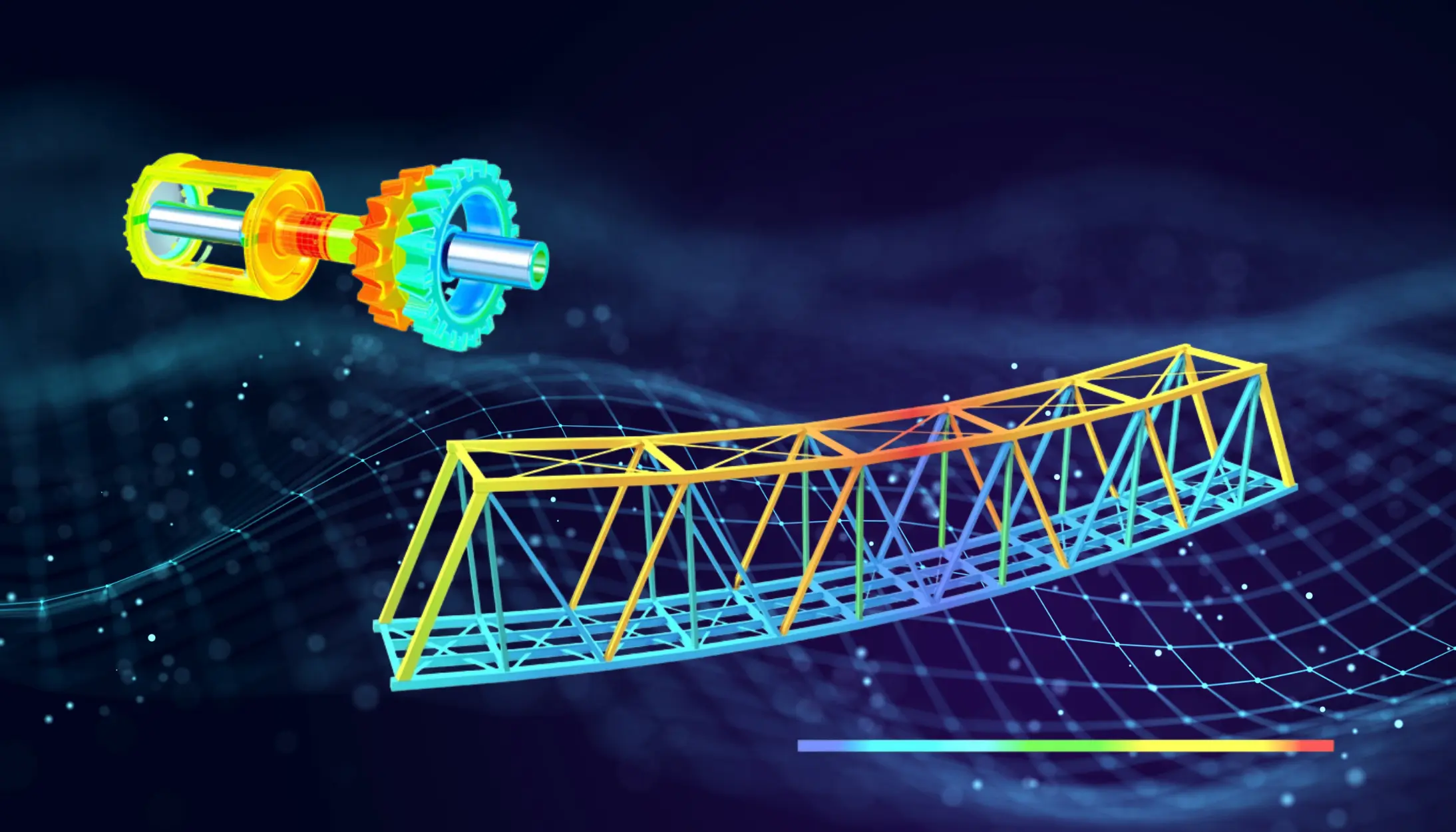

When implementing engineering designs, engineers use the numerical method of Finite Element Analysis (FEA) as their essential analysis tool. FEA is an analytical tool to predict product responses toward operational forces consisting of heat, vibration, fluid motion, and structural applications.

Engineers conduct finite element analysis to probe product weaknesses before they implement design enhancements and manufacturing.

This article explains what is finite element analysis is while detailing its structural and mechanical applications, finite element analysis in design, and effective learning approaches.

What is Finite Element Analysis?

The computational approach of Finite Element Analysis (FEA) divides complex systems into smaller components referred to as elements. Nodes connect these elements into a finite element analysis model, which stands as a representative structure model.

The approach implements mathematical formulas that run computer simulations to display how objects respond when faced with multiple forces. Finite Element Analysis Simulation plays a critical role in engineering design by predicting structural performance before manufacturing.

How does FEA work in structural and mechanical analysis?

Most structural and mechanical engineers use the finite element analysis method to analyse stress, together with strain and material deformation. Design engineers employ finite element analysis as a virtual prototype testing tool, which cuts down the requirement for physical tests.

In the automotive, aerospace, construction, and biomedical engineering industries, FEA ensures safety while providing efficiency and cost-effectiveness.

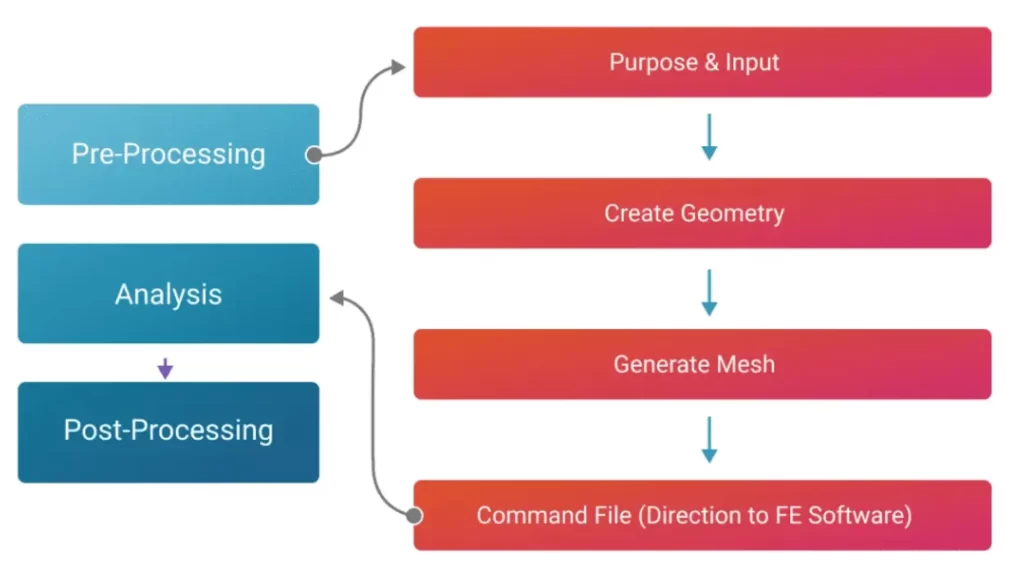

Steps involved in performing Finite Element Analysis:

The finite element analysis method performs structured simulation procedures for accurate outcomes. Engineering teams conduct design testing using finite element analysis models before manufacturing. Preprocessing stands as the first step before the solution takes place, followed by postprocessing.

01. Preprocessing (model creation, meshing, material properties)

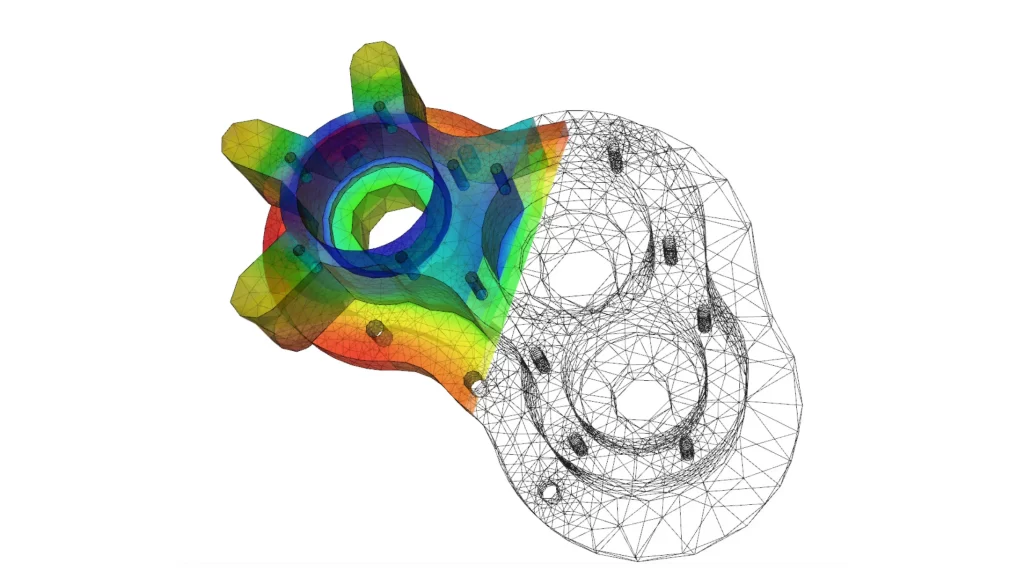

Finite element analysis begins with preprocessing steps that form its essential base in the design process. Engineers develop a digital model that depicts the product as well as specifying its structural contours and substance characteristics. The analytical model requires meshing to segment its components into smaller units.

The precision of finite element analysis results depends on selecting appropriate 1D, 2D, and 3D element types. Every mesh element requires specific property assignments, including its elasticity along with its density and thermal conductivity factors.

02. Solution (applying loads and boundary conditions)

At this point, engineers introduce heat as well as forces and pressure onto elements throughout the finite element analysis model. Simulation of real-world conditions happens through the deployment of boundary conditions that impose fixed supports and movement restrictions.

FEA software computes stress and strain results as well as displacement outcomes by solving mathematical equations.

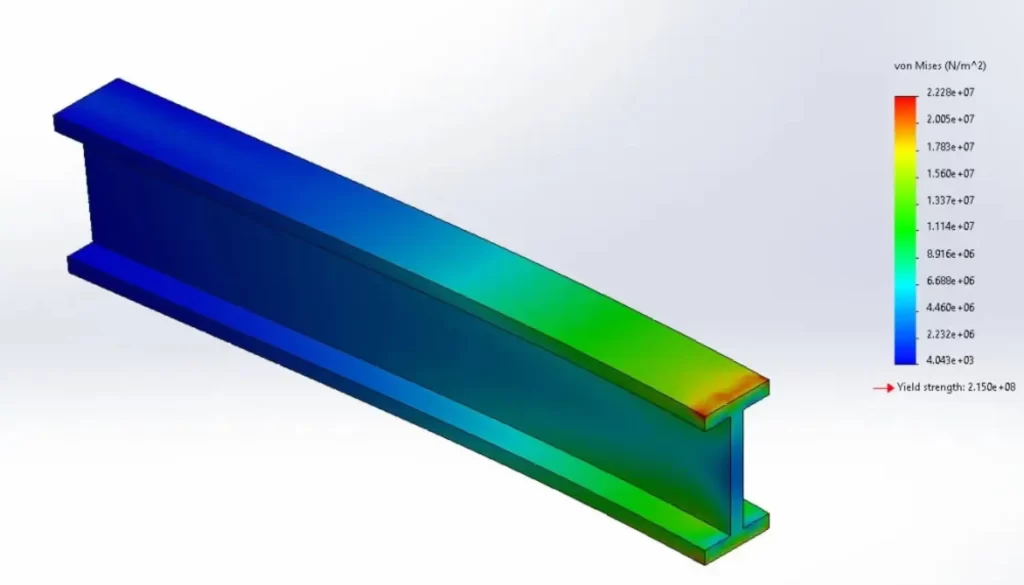

03. Postprocessing (analyzing results, visualization)

Simulation results are subjected to post-processing analytical procedures. Through their analysis, engineers check for patterns of deformation together with pressure distribution and safety levels.

Colour-coded stress maps exemplify how finite element analysis displays test results for evaluation purposes. The design verification process inspects whether the product satisfies both industrial quality benchmarks and necessary safety prerequisites.

FEA Training Online Course helps you to get trained on Finite Element Analysis from basic concepts to advanced simulation analysis techniques. FEA experts offered live hands-on training on it.

Importance of accuracy in Finite Element Analysis simulations

Engineers rely on correct finite element analysis (FEA) results for making essential engineering choices. Structural predictions under different conditions rely on finite element analysis models, which engineers utilize for their work. Design failures and manufacturing costs increase dramatically due to small simulation errors.

1. Quality of Mesh Refinement

An FEA simulation’s accuracy depends directly on the quality of its mesh. Engineering results improve with increasing mesh density, yet insufficient meshing leads to flawed strain distribution. Engineers conduct mesh refinement procedures for precise calculations because improper results can occur due to ambiguous outcomes.

2. Correct Application of Boundary Conditions

Boundary condition implementation plays a vital role in achieving accurate results during finite element analysis in design. The application of inappropriate constraints generates false results that reduce product reliability. Engineers need to define their design parameters precisely to achieve better accuracy.

3. Precise Material Property Definitions

The success of FEA simulations depends on material properties that operators input accurately. Defining material elasticity and thermal abilities, and overall strength, leads to flawed prediction outcomes. Finite element analysis models need proper definitions to guarantee real-world simulation accuracy.

4. Selection of Suitable Element Types

Different element types for FEA determine the accuracy levels. Design complexity requires various element dimensions from 1D and 2D up to 3D. When choosing elements that are not appropriate for each simulation model, they might generate inaccurate results.

Read more: Which are the best FEA software: ABAQUS or ANSYS ?

Role of FEA in product design and development

FEA stands as a fundamental method that designers use for product development processes. The application of this technique enables safer designs combined with improved performance as well as cost reduction.

1. Evaluating Stress and Strain

By performing FEA, engineers discover the material’s reactions to different forces, such as tension and compression, as well as bending forces. A properly designed finite element analysis model delivers precise stress and strain evaluation. It also stops structural failure from happening.

2. Optimising Weight and Strength

Through the finite element analysis method, designers achieve strength retention when they decrease material quantities. Strong, lightweight materials that benefit fuel efficiency and performance represent essential goals in the automotive and aerospace industries.

3. Improving Thermal and Fluid Flow Performance

The analysis method uses FEA to measure both fluid dynamics behaviour and heat distribution patterns. Aerospace and electronic industries utilise FEA to optimise cooling system designs, which enhances system efficiency while preventing overheating.

4. Enhancing Safety and Durability

Engineers use a proper selection of finite element analysis elements to verify that products satisfy safety requirements. Medical device industries apply FEA for implant and prosthetic durability testing, which ensures regulatory compliance.

Advantages of using FEA for optimizing designs before manufacturing

FEA is a vital design tool that allows engineers to enhance product designs before manufacturing. Engineers benefit from this tool by developing better designs at reduced expenses and increased performance outcomes. A company achieves structural optimisation through the finite element analysis without expensive prototypes.

1. Cost Savings

Through FEA, companies cut down their manufacturing costs by eliminating the necessity of physical testing. Through the finite element analysis method, engineers create virtual simulations that remove physical testing and avoid expensive mistakes in design.

2. Faster Product Development

The design process using FEA leads to the acceleration of product development speed. Engineers utilise simulation to evaluate several product designs before final production begins. The company’s ability to market new products accelerates because of this process.

3. Risk Reduction

Applying finite element analysis explained techniques helps engineers locate product weaknesses at an initial stage. The system identifies potential failures in real-world applications, thereby creating safer products. Structural integrity depends on FEA because it evaluates different conditions against finite element analysis element types.

4. Better Performance and Reliability

The efficiency of a design process increases through FEA because it optimises material distribution and structural integrity strength levels. Product durability improves while performance reliability increases for items operating under environmental conditions and external loads.

Finite Element Analysis Model

A physical structure becomes present in the finite element analysis model through its nodes and elements. Engineers apply this model for the study of various design situations to enhance product performance. Analysts utilize the finite element analysis method to make predictions about product stress, strain, and deformations before beginning manufacturing.

The application of FEA includes evaluations in numerous domains.

- Automotive crash testing simulations – Ensures vehicle safety and impact resistance.

- The analysis of bridge and building structures checks their stability when tested under various loads.

- Aerospace component thermal evaluations – Test materials for heat resistance in extreme conditions.

- Biomedical implants and prosthetics testing – Ensures durability and compatibility with the human body.

Conclusion

Finite Element Analysis (FEA) is a vital instrument that engineers and designers utilize daily. FEA benefits engineers by predicting and enhancing product performance. Knowledge of FEA enables professionals to perform efficient evaluations of structures and mechanical systems.

Expertise in finite element analysis fundamental concepts enables professionals to thrive in their workplace. For professional training in FEA, reach out to PIGSO LEARNING to boost your engineering skills. We offer focused training for students and professionals, giving them skills relevant to the industry to excel in their professional lives.

FAQs

1. What is FEA – Finite Element Analysis?

FEA stands for a process that examines structural responses against forces and heat conditions, along with other factors. Engineers break complex objects into multiple parts to achieve better performance analysis through this method.

2. What practical functions does Finite Element Analysis (FEA) enable?

The FEA serves multiple industries, including automotive, aerospace, construction, and healthcare. Engineers deploy FEA to conduct car crash safety tests and design aircraft frameworks while developing resilient structures and medical equipment. The evaluation process ensures products achieve safety standards and operational efficiency before manufacturing.

3. How accurate is FEA?

FEA produces accurate results only after creating an appropriate and well-built model. Better mesh elements paired with precise material characteristics and proper boundary constraints lead to more accurate results. Engineers optimize these factors to achieve specific outcomes.

4. What are the core finite element analysis element sets?

FEA operates with three element types.

Beams (1D) – For long, thin structures like bridges.

Shells (2D) – For surfaces like car bodies.

Solids (3D) – For solid objects like engine parts.

The selection process for elements is based on how sophisticated the analyzed structure is.

5. How to learn Finite Element Analysis?

You should begin learning FEA by taking educational resources from online courses, articles, and books. After learning basic software skills in any FEA Software Applications like Abaqus or ANSYS, move on to real-world project assignments. Students learn to solve problems and find solutions more effectively through practical application.

I’m a passionate content writer who crafts compelling, audience-focused content. I specialize in turning ideas into engaging words, ensuring every piece delivers value, connects, and drives results.